Simulation and conceptual design of an aniline production process from catalytic hydrogenation of nitrobenzene in ChemCAD

DOI:

https://doi.org/10.18779/ingenio.v7i2.873Keywords:

aniline, nitrobenzene, ChemCAD, catalytic hydrogenation, conceptual designAbstract

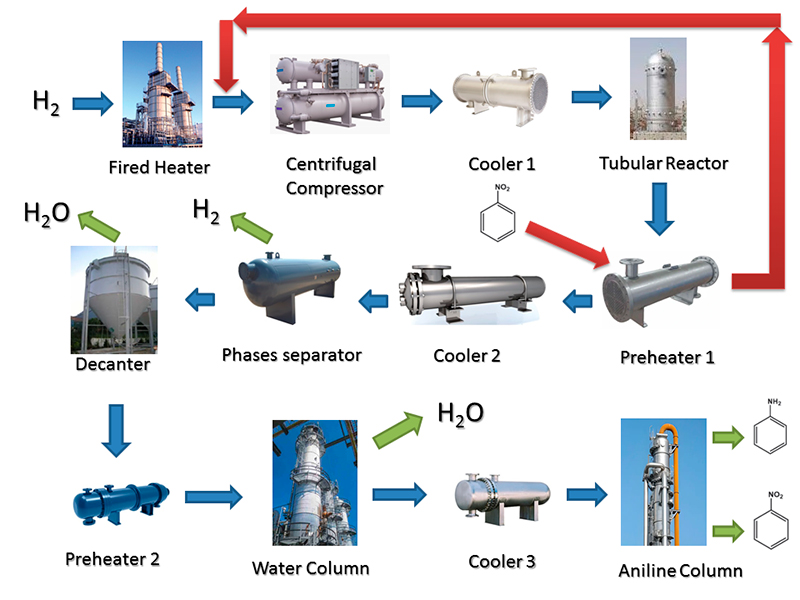

Aniline is a very important compound in organic chemistry, mainly used to synthesize polyurethane and its precursors. In the present work, the simulation and conceptual design of an aniline production process through the catalytic hydrogenation route of nitrobenzene was carried out using ChemCADÒ simulator. The simulated aniline production process consisted of a fired heater, a tubular reactor, several heat exchangers, a phase separator, a decanter, as well as two distillation columns. By means of the simulation, the temperatures, pressures, mass flowrates and enthalpies of the main intermediate and final streams were known, as well as the main operating and design parameters of some equipment. About 1,743 kg/h of aniline with a purity of 99.78% are produced at the top stream of the second distillation column, while about 49,881 kg/h of hydrogen are obtained as a by-product in the phase separator. In this work a first-of-its-kind ChemCAD simulation model was obtained in this work, which can be utilized for further optimization studies and tasks involving the increment of aniline purity, yields and productivity.

Downloads

References

H. J. Patel, Handbook of Chemical Process Industries. Boca Raton, USA: CRC Press, 2024.

R. V. Brovko, L. S. Mushinsky, A. R. Latypova, M. G. Sulman, V. G. Matveeva, and V. Y. Doluda, "Evaluation of Nitrobenzene Hydrogenation Kinetic Particularities Over Mono and Bimetallic Ni Containing Hypercrosslinked Polystyrene," Chemical Engineering Transactions, vol. 86, pp. 883-888, 2021.

Javaid and C. S. Bildea, "Design and Control of an Integrated Toluene-Aniline Production Plant a Preliminary Study," International Journal of Chemical Engineering and Applications, vol. 8, no. 4, pp. 267-271, 2017.

S. Couto, L. M. Madeira, C. P. Nunes, and P. Araújo, "Hydrogenation of Nitrobenzene over a Pd/Al2O3 Catalyst – Mechanism and Effect of the Main Operating Conditions," Chemical Engineering and Technology, vol. 38, no. 9, pp. 1625-1636, 2015.

Q. Zhang et al., "Highly Efficient Hydrogenation of Nitrobenzene to Aniline over Pt/CeO2 Catalysts: The Shape Effect of the Support and Key Role of Additional Ce3+ Sites," ACS Catalysis, vol. 10, pp. 10350-10363, 2020.

A.-J. Wang et al., "Efficient Reduction of Nitrobenzene to Aniline with a Biocatalyzed Cathode," Environmental Science and Technology, vol. 45, pp. 10186-10193, 2011.

C. G. A. Morisse et al., "Toward High Selectivity Aniline Synthesis Catalysis at Elevated Temperatures," Industrial & Engineering Chemistry Research, vol. 60, pp. 17917-17927, 2021.

J. Wang, C. Du, Q. Wei, and W. Shen, "Two-Dimensional Pd Nanosheets with Enhanced Catalytic Activity for Selective Hydrogenation of Nitrobenzene to Aniline," Energy Fuels, vol. 35, pp. 4358-4366, 2021.

S. Gómez, C. Torres, J. L. García, C. P. Apesteguía, and P. Reyes, "Hydrogenation of Nitrobenzene on Au/ZrO2 catalysts," J. Chil. Chem. Soc., vol. 57, no. 2, pp. 1194-1198, 2012.

S. Diao, W. Qian, G. Luo, F. Wei, and Y. Wang, "Gaseous catalytic hydrogenation of nitrobenzene to aniline in a two-stage fluidized bed reactor," Applied Catalysis A: General, vol. 286, pp. 30-35, 2005.

Y. Jiang, X. Li, Z. Qin, and H. Ji, "Preparation of Ni/bentonite catalyst and its applications in the catalytic hydrogenation of nitrobenzene to aniline," Chinese Journal of Chemical Engineering, vol. 24, pp. 1195-1200, 2016.

L. Petrov, K. Kumbilieva, and N. Kirkov, "Kinetic Model of Nitrobenzene Hydrogenation to Aniline over Industrial Copper Catalyst Considering the Effects of Mass Transfer and Deactivation," Applied Catalysis, vol. 59, pp. 31-43, 1990.

Z. A. Aboosadi, M. R. Rahimpour, and A. Jahanmiri, "A novel integrated thermally coupled configuration for methane-steam reforming and hydrogenation of nitrobenzene to aniline," International Journal of Hydrogen Energy, vol. 36, pp. 2960-2968, 2011.

N. S. Abo-Ghander, J. R. Grace, S. S. E. H. Elnashaie, and C. J. Lim, "Modeling of a novel membrane reactor to integrate dehydrogenation of ethylbenzene to styrene with hydrogenation of nitrobenzene to aniline," Chemical Engineering Science, vol. 63, pp. 1817-1826, 2008.

Intratec Solutions, "Aniline Production from Nitrobenzene (Liquid-Phase)," Chemical Engineering, vol. 123, no. 3, p. 48, 2016.

Z. A. Abdel-Rahman and O. S. Latef, "Process simulation of benzene separation column of linear alkyl benzene (lab)plant usign ChemCAD," Tikrit Journal of Eng. Sciences, vol. 15, no. 1, pp. 17-29, 2008.

L. Petrescu, A. Imre-Lucaci, and C. I. Berci, "Modelling and simulation of fules production from syngas," STUDIA UBB CHEMIA, vol. LXII, no. 4, pp. 231-240, 2017.

B. Kökdemir and N. Acarali, "A novel study on CHEMCAD simulation of isopropyl alcohol dehydrogenation process development," Journal of the Indian Chemical Society, vol. 98, p. 100035, 2021.

E. Benanti, C. Freda, V. Lorefice, G. Braccio, and V. k. Sharma, "Simulation of olive puits pyrolysis in a rotary kiln plant," Thermal Science, vol. 15, no. 1, pp. 145-158, 2011.

C. Chilev, F. Lamari, and P. Langlois, "Numerical Simulation of a Valorisation-Oriented Hybrid Process for the Bio-Oil-Related Separation of Acetol and Acetic Acid," ChemEngineering, vol. 8, p. 2, 2024.

S. Dibyo, I. D. Irianto, S. Bakhri, and M. Pancoko, "Thermal design of cooler in the fuel handling pneumatic system of RDE," IOP Conf. Series: Materials Science and Engineering, vol. 830, p. 022018, 2020.

N. Amenaghawon and S. E. Ogbeide, "Modelling, simulation and control of ethyl acetate reactive distillation column using ChemCAD," Journal of Engineering and Applied Sciences, vol. 4, pp. 16-33, 2012.

Pérez, E. J. Pérez, and R. M. Segura, "Simulation of the styrene production process via catalytic dehydrogenation of ethylbenzene using CHEMCAD® process simulator," Tecnura, vol. 21, no. 53, pp. 15-31, 2017.

Pérez, E. J. Pérez, and R. M. Segura, "Simulation of the acrylic acid production process through catalytic oxidation of gaseous propylene using ChemCAD® simulator," Ingeniare. Revista chilena de ingeniería, vol. 27, no. 1, pp. 142-150, 2019.

Pérez, E. Ranero, E. J. Pérez, and N. Liaño, "Simulación del proceso de producción del cumeno mediante el simulador ChemCAD®," RECyT, vol. 22, no. 33, pp. 38–46, 2020.

Pérez, E. Ranero, and E. J. Pérez, "Simulación del proceso de producción de anhídrido maleico mediante el simulador ChemCAD®," MUTIS, vol. 11, no. 2, pp. 8-21, 2021.

Pérez, J. G. Baltá, J. R. Montalván, E. Ranero, and E. J. Pérez, "Simulation of the ethylene oxide production process in ChemCAD® simulator," RECyT, vol. 24, no. 37, pp. 15-24, 2022.

R. Sinnott and G. Towler, Chemical Engineering Design, 6th ed. Oxford, United Kingdom: Butterworth-Heinemann, 2020.

S. M. Walas, Chemical Process Equipment Selection and Design. Boston, USA: Butterworth-Heinemann, 1990.

N. P. Cheremisinoff, Handbook of Chemical Processing Equipment. Boston, USA: Butterworth-Heinemann, 2000.

M. S. Peters, K. D. Timmerhaus, and R. E. West, Plant Design and Economics for Chemical Engineers, 5th ed. New York, USA: McGraw-Hill, 2003.

J. R. Couper, W. R. Penney, J. R. Fair, and S. M. Walas, Chemical Process Equipment Selection and Design, 3rd ed. Oxford, U.K.: Butterworth-Heinemann, 2012.

D. W. Green and M. Z. Southard, Perry's Chemical Engineers' Handbook, 9th ed. New York, USA: McGraw-Hill Education, 2019.

S. Jenkins, "Economic Indicators," Chemical Engineering, vol. 131, no. 3, p. 48, 2024.

P. H. Nayak, Proposed new project for Manufacturing of Aniline and Nitro Benzene. Ahmedabad, India: Satva Environ Consultancy, 2018.

S. M. Hall, Rules of Thumb for Chemical Engineers, 6th ed. Oxford, United Kingdom: Elsevier, 2018.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Amaury Pérez Sánchez, Yerelis Pons García, Lennis Leidy Basulto Cruz, Maria Isabel La Rosa Veliz

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Licensing Agreement

This journal provides free access to its content through its website following the principle that making research available free of charge to the public supports a larger exchange of global knowledge.

Web content of the journal is distributed under a Attribution-NonCommercial-ShareAlike 4.0 International.

Authors may adopt other non-exclusive license agreements for the distribution of the version of the published work, provided that the initial publication in this journal is indicated. Authors are allowed and recommended to disseminate their work through the internet before and during the submission process, which can produce interesting exchanges and increase citations of the published work.