Literature review on the use of deep learning focused on automated optical inspection systems for surface defect detection in the manufacturing sector

DOI:

https://doi.org/10.18779/ingenio.v6i2.680Keywords:

manufacturing, deep learning, convolutional neural networks, optimization algorithms, automated optical inspection, generalization, imbalanceAbstract

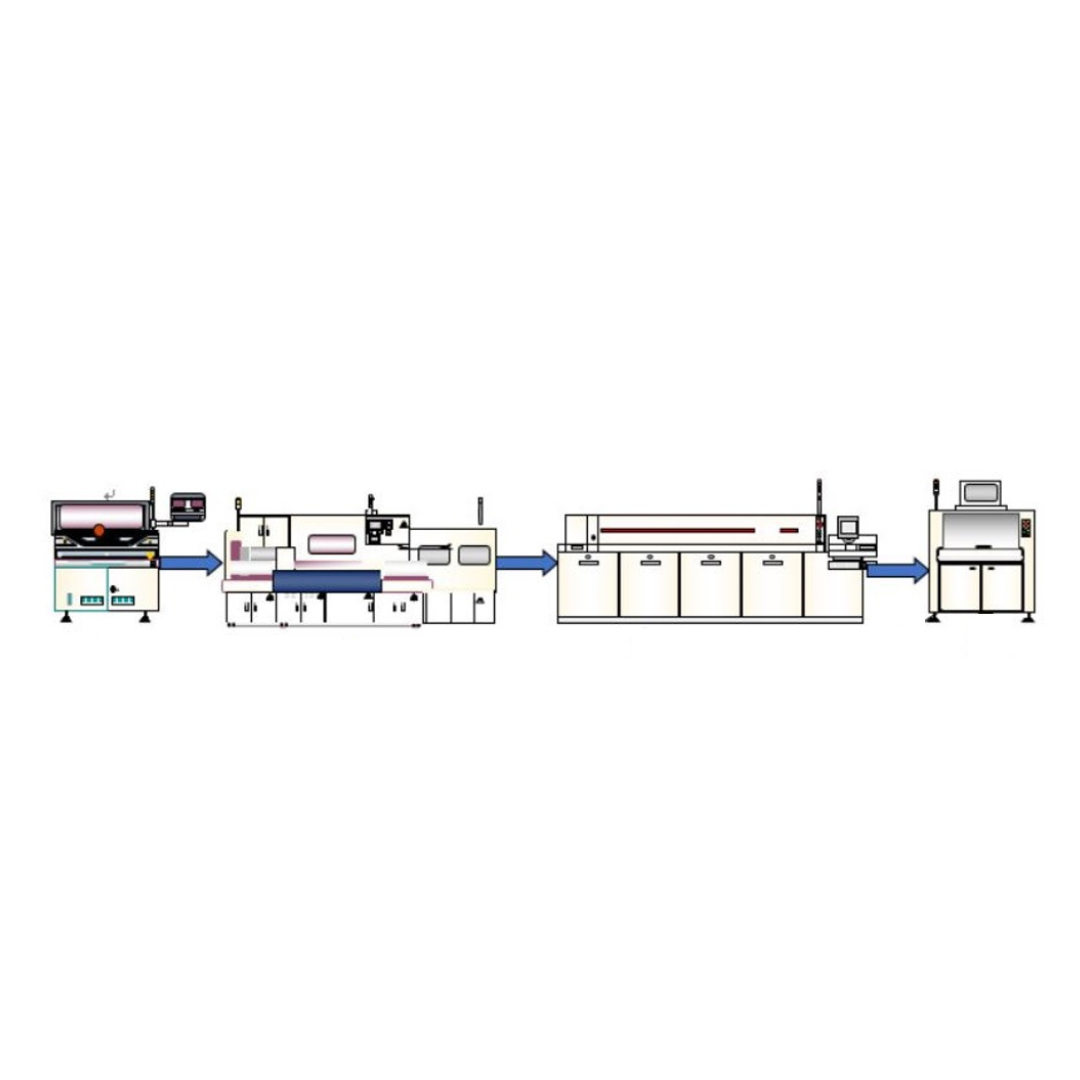

The manufacturing industry uses supervised machine learning methodologies to improve inspection processes through machine vision. Automated optical inspection offers efficiency in the inspection process for the detection of defects in the manufacture of various products. This work contributes with the identification of those limitations in data processing based on defined rule sets and process domain management. A literature review is proposed on the use of deep learning focused on automated optical inspection systems for the detection of surface defects in the manufacturing sector. The proposed objective is to identify the different architectures oriented on convolutional neural networks applied in optical inspection systems to automate the extraction of features or patterns. By means of the exploration of relevant works, a total of 47 selected papers that address generalization problems and optimization techniques are identified. Finally, the information of the different architectures is contrasted for the elaboration of a comparative table that evidence improvements in the accuracy of the optical inspection systems by means of the percentage achieved. These results contribute as an input to the existing body of literature for improvements in the manufacturing sector.

Downloads

References

R. Alvarado-Salazar and J. Llerena-Izquierdo, “Revisión de la literatura sobre el uso de Inteligencia Artificial enfocada a la atención de la discapacidad visual,” Revista InGenio, vol. 5, no. 1, pp. 10–21, 2022, doi: https://doi.org/10.18779/ingenio.v5i1.472.

H.-I. Lin and F. S. Wibowo, “Image Data Assessment Approach for Deep Learning-Based Metal Surface Defect-Detection Systems,” IEEE Access, vol. 9, pp. 47621–47638, 2021, doi: 10.1109/ACCESS.2021.3068256.

A. A. R. M. A. Ebayyeh and A. Mousavi, “A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry,” IEEE Access, vol. 8, pp. 183192–183271, 2020, doi: 10.1109/ACCESS.2020.3029127.

Q. Luo et al., “Automated Visual Defect Classification for Flat Steel Surface: A Survey,” IEEE Trans Instrum Meas, vol. 69, no. 12, pp. 9329–9349, 2020, doi: 10.1109/TIM.2020.3030167.

Y.-T. Li, P. Kuo, and J.-I. Guo, “Automatic Industry PCB Board DIP Process Defect Detection System Based on Deep Ensemble Self-Adaption Method,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 2, pp. 312–323, 2021, doi: 10.1109/TCPMT.2020.3047089.

A. M. Kamoona, A. K. Gostar, A. Bab-Hadiashar, and R. Hoseinnezhad, “Point Pattern Feature-Based Anomaly Detection for Manufacturing Defects, in the Random Finite Set Framework,” IEEE Access, vol. 9, pp. 158672–158681, 2021, doi: 10.1109/ACCESS.2021.3130261.

Y. Yang et al., “A lightweight deep learning algorithm for inspection of laser welding defects on safety vent of power battery,” Comput Ind, vol. 123, 2020, doi: 10.1016/j.compind.2020.103306.

L. C. Chen et al., “Edge-glued wooden panel defect detection using deep learning,” Wood Sci Technol, vol. 56, no. 2, pp. 477–507, Mar. 2022, doi: 10.1007/S00226-021-01316-3/TABLES/9.

Y. C. Huang, K. C. Hung, C. C. Liu, T. H. Chuang, and S. J. Chiou, “Customized Convolutional Neural Networks Technology for Machined Product Inspection,” Applied Sciences 2022, Vol. 12, Page 3014, vol. 12, no. 6, p. 3014, Mar. 2022, doi: 10.3390/APP12063014.

C. H. Lin, S. H. Wang, and C. J. Lin, “Using convolutional neural networks for character verification on integrated circuit components of printed circuit boards,” Applied Intelligence 2019 49:11, vol. 49, no. 11, pp. 4022–4032, May 2019, doi: 10.1007/S10489-019-01486-5.

P. M. Bhatt et al., “Image-Based Surface Defect Detection Using Deep Learning: A Review,” J Comput Inf Sci Eng, vol. 21, no. 4, Aug. 2021, doi: 10.1115/1.4049535/1094064.

R. K. Sheu, L. C. Chen, M. S. Pardeshi, K. C. Pai, and C. Y. Chen, “AI Landing for Sheet Metal-Based Drawer Box Defect Detection Using Deep Learning (ALDB-DL),” Processes 2021, Vol. 9, Page 768, vol. 9, no. 5, p. 768, Apr. 2021, doi: 10.3390/PR9050768.

H. I. Lin and F. S. Wibowo, “Image Data Assessment Approach for Deep Learning-Based Metal Surface Defect-Detection Systems,” IEEE Access, vol. 9, pp. 47621–47638, 2021, doi: 10.1109/ACCESS.2021.3068256.

J. W. Wang, C. C. Wang, and T. C. Cheng, “AI-based Automatic Optical Inspection of Glass Bubble Defects,” ACM International Conference Proceeding Series, pp. 242–246, Apr. 2020, doi: 10.1145/3396743.3396768.

S. A. Reynoso Farnes, D. M. Tsai, and W. Y. Chiu, “Autofocus Measurement for Electronic Components Using Deep Regression,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 4, pp. 697–707, Apr. 2021, doi: 10.1109/TCPMT.2021.3060809.

J. Llerena-Izquierdo, F. Procel-Jupiter, and A. Cunalema-Arana, “Mobile Application with Cloud-Based Computer Vision Capability for University Students’ Library Services,” Advances in Intelligent Systems and Computing, vol. 1277, pp. 3–15, Jun. 2021, doi: 10.1007/978-3-030-60467-7_1.

H. Giang Nguyen, M. Meiners, L. Schmidt, and J. Franke, “Deep learning-based automated optical inspection system for crimp connections,” 2020 10th International Electric Drives Production Conference, EDPC 2020 - Proceedings, Dec. 2020, doi: 10.1109/EDPC51184.2020.9388203.

M. A. Mallaiyan Sathiaseelan, O. P. Paradis, S. Taheri, and N. Asadizanjani, “Why Is Deep Learning Challenging for Printed Circuit Board (PCB) Component Recognition and How Can We Address It?,” undefined, vol. 5, no. 1, 2021, doi: 10.3390/CRYPTOGRAPHY5010009.

Y. T. Li, P. Kuo, and J. I. Guo, “Automatic Industry PCB Board DIP Process Defect Detection System Based on Deep Ensemble Self-Adaption Method,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 2, pp. 312–323, Feb. 2021, doi: 10.1109/TCPMT.2020.3047089.

G. S. Junior, J. Ferreira, C. Millán-Arias, R. Daniel, A. C. Junior, and B. J. T. Fernandes, “Ceramic Cracks Segmentation with Deep Learning,” Applied Sciences 2021, Vol. 11, Page 6017, vol. 11, no. 13, p. 6017, Jun. 2021, doi: 10.3390/APP11136017.

K. J. Wang, H. Fan-Jiang, and Y. X. Lee, “A multiple-stage defect detection model by convolutional neural network,” Comput Ind Eng, vol. 168, p. 108096, Jun. 2022, doi: 10.1016/J.CIE.2022.108096.

J. Li, N. Cai, Z. Mo, G. Zhou, and H. Wang, “IC solder joint inspection via generator-adversarial-network based template,” Mach Vis Appl, vol. 32, no. 4, pp. 1–16, Jul. 2021, doi: 10.1007/S00138-021-01218-1/TABLES/4.

X. Zheng, J. Chen, H. Wang, S. Zheng, and Y. Kong, “A deep learning-based approach for the automated surface inspection of copper clad laminate images,” Applied Intelligence 2020 51:3, vol. 51, no. 3, pp. 1262–1279, Sep. 2020, doi: 10.1007/S10489-020-01877-Z.

H. G. Nguyen, R. Habiboglu, and J. Franke, “Enabling deep learning using synthetic data: A case study for the automotive wiring harness manufacturing,” Procedia CIRP, vol. 107, pp. 1263–1268, Jan. 2022, doi: 10.1016/J.PROCIR.2022.05.142.

A. Kulkarni and C. Xu, “A Deep Learning Approach in Optical Inspection to Detect Hidden Hardware Trojans and Secure Cybersecurity in Electronics Manufacturing Supply Chains,” Front Mech Eng, vol. 7, Jul. 2021, doi: 10.3389/FMECH.2021.709924.

N. Hussain et al., “A deep neural network and classical features based scheme for objects recognition: an application for machine inspection,” Multimed Tools Appl, pp. 1–23, Apr. 2020, doi: 10.1007/S11042-020-08852-3/TABLES/8.

L.-C. Chen et al., “Edge-glued wooden panel defect detection using deep learning,” Wood Sci Technol, vol. 56, no. 2, pp. 477–507, 2022, doi: 10.1007/s00226-021-01316-3.

T.-H. Kim, H.-R. Kim, and Y.-J. Cho, “Product Inspection Methodology via Deep Learning: An Overview,” Sensors , vol. 21, no. 15. 2021. doi: 10.3390/s21155039.

J. Lehr, A. Sargsyan, M. Pape, J. Philipps, and J. Krüger, “Automated Optical Inspection Using Anomaly Detection and Unsupervised Defect Clustering,” IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, vol. 2020-September, pp. 1235–1238, Sep. 2020, doi: 10.1109/ETFA46521.2020.9212172.

X. Zheng, H. Wang, J. Chen, Y. Kong, and S. Zheng, “A Generic Semi-Supervised Deep Learning-Based Approach for Automated Surface Inspection,” IEEE Access, vol. 8, pp. 114088–114099, 2020, doi: 10.1109/ACCESS.2020.3003588.

Y. Yang et al., “A lightweight deep learning algorithm for inspection of laser welding defects on safety vent of power battery,” Comput Ind, vol. 123, Dec. 2020, doi: 10.1016/j.compind.2020.103306.

Y. F. Chen, F. S. Yang, E. Su, and C. C. Ho, “Automatic Defect Detection System Based on Deep Convolutional Neural Networks,” 2019 International Conference on Engineering, Science, and Industrial Applications, ICESI 2019, Aug. 2019, doi: 10.1109/ICESI.2019.8863029.

V. A. Adibhatla et al., “Unsupervised Anomaly Detection in Printed Circuit Boards through Student–Teacher Feature Pyramid Matching,” Electronics 2021, Vol. 10, Page 3177, vol. 10, no. 24, p. 3177, Dec. 2021, doi: 10.3390/ELECTRONICS10243177.

K.-C. Li et al., “Intelligent Identification of MoS2 Nanostructures with Hyperspectral Imaging by 3D-CNN,” Nanomaterials 2020, Vol. 10, Page 1161, vol. 10, no. 6, p. 1161, Jun. 2020, doi: 10.3390/NANO10061161.

B. M. Haddad, S. F. Dodge, L. J. Karam, N. S. Patel, and M. W. Braun, “Locally Adaptive Statistical Background Modeling with Deep Learning-Based False Positive [1] R. Alvarado-Salazar and J. Llerena-Izquierdo, “Revisión de la literatura sobre el uso de Inteligencia Artificial enfocada a la atención de la discapacidad visual,” Revista InGenio, vol. 5, no. 1, pp. 10–21, 2022, doi: https://doi.org/10.18779/ingenio.v5i1.472.

H.-I. Lin and F. S. Wibowo, “Image Data Assessment Approach for Deep Learning-Based Metal Surface Defect-Detection Systems,” IEEE Access, vol. 9, pp. 47621–47638, 2021, doi: 10.1109/ACCESS.2021.3068256.

A. A. R. M. A. Ebayyeh and A. Mousavi, “A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry,” IEEE Access, vol. 8, pp. 183192–183271, 2020, doi: 10.1109/ACCESS.2020.3029127.

Q. Luo et al., “Automated Visual Defect Classification for Flat Steel Surface: A Survey,” IEEE Trans Instrum Meas, vol. 69, no. 12, pp. 9329–9349, 2020, doi: 10.1109/TIM.2020.3030167.

Y.-T. Li, P. Kuo, and J.-I. Guo, “Automatic Industry PCB Board DIP Process Defect Detection System Based on Deep Ensemble Self-Adaption Method,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 2, pp. 312–323, 2021, doi: 10.1109/TCPMT.2020.3047089.

A. M. Kamoona, A. K. Gostar, A. Bab-Hadiashar, and R. Hoseinnezhad, “Point Pattern Feature-Based Anomaly Detection for Manufacturing Defects, in the Random Finite Set Framework,” IEEE Access, vol. 9, pp. 158672–158681, 2021, doi: 10.1109/ACCESS.2021.3130261.

Y. Yang et al., “A lightweight deep learning algorithm for inspection of laser welding defects on safety vent of power battery,” Comput Ind, vol. 123, 2020, doi: 10.1016/j.compind.2020.103306.

L. C. Chen et al., “Edge-glued wooden panel defect detection using deep learning,” Wood Sci Technol, vol. 56, no. 2, pp. 477–507, Mar. 2022, doi: 10.1007/S00226-021-01316-3/TABLES/9.

Y. C. Huang, K. C. Hung, C. C. Liu, T. H. Chuang, and S. J. Chiou, “Customized Convolutional Neural Networks Technology for Machined Product Inspection,” Applied Sciences 2022, Vol. 12, Page 3014, vol. 12, no. 6, p. 3014, Mar. 2022, doi: 10.3390/APP12063014.

C. H. Lin, S. H. Wang, and C. J. Lin, “Using convolutional neural networks for character verification on integrated circuit components of printed circuit boards,” Applied Intelligence 2019 49:11, vol. 49, no. 11, pp. 4022–4032, May 2019, doi: 10.1007/S10489-019-01486-5.

P. M. Bhatt et al., “Image-Based Surface Defect Detection Using Deep Learning: A Review,” J Comput Inf Sci Eng, vol. 21, no. 4, Aug. 2021, doi: 10.1115/1.4049535/1094064.

R. K. Sheu, L. C. Chen, M. S. Pardeshi, K. C. Pai, and C. Y. Chen, “AI Landing for Sheet Metal-Based Drawer Box Defect Detection Using Deep Learning (ALDB-DL),” Processes 2021, Vol. 9, Page 768, vol. 9, no. 5, p. 768, Apr. 2021, doi: 10.3390/PR9050768.

H. I. Lin and F. S. Wibowo, “Image Data Assessment Approach for Deep Learning-Based Metal Surface Defect-Detection Systems,” IEEE Access, vol. 9, pp. 47621–47638, 2021, doi: 10.1109/ACCESS.2021.3068256.

J. W. Wang, C. C. Wang, and T. C. Cheng, “AI-based Automatic Optical Inspection of Glass Bubble Defects,” ACM International Conference Proceeding Series, pp. 242–246, Apr. 2020, doi: 10.1145/3396743.3396768.

S. A. Reynoso Farnes, D. M. Tsai, and W. Y. Chiu, “Autofocus Measurement for Electronic Components Using Deep Regression,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 4, pp. 697–707, Apr. 2021, doi: 10.1109/TCPMT.2021.3060809.

J. Llerena-Izquierdo, F. Procel-Jupiter, and A. Cunalema-Arana, “Mobile Application with Cloud-Based Computer Vision Capability for University Students’ Library Services,” Advances in Intelligent Systems and Computing, vol. 1277, pp. 3–15, Jun. 2021, doi: 10.1007/978-3-030-60467-7_1.

H. Giang Nguyen, M. Meiners, L. Schmidt, and J. Franke, “Deep learning-based automated optical inspection system for crimp connections,” 2020 10th International Electric Drives Production Conference, EDPC 2020 - Proceedings, Dec. 2020, doi: 10.1109/EDPC51184.2020.9388203.

M. A. Mallaiyan Sathiaseelan, O. P. Paradis, S. Taheri, and N. Asadizanjani, “Why Is Deep Learning Challenging for Printed Circuit Board (PCB) Component Recognition and How Can We Address It?,” undefined, vol. 5, no. 1, 2021, doi: 10.3390/CRYPTOGRAPHY5010009.

Y. T. Li, P. Kuo, and J. I. Guo, “Automatic Industry PCB Board DIP Process Defect Detection System Based on Deep Ensemble Self-Adaption Method,” IEEE Trans Compon Packaging Manuf Technol, vol. 11, no. 2, pp. 312–323, Feb. 2021, doi: 10.1109/TCPMT.2020.3047089.

G. S. Junior, J. Ferreira, C. Millán-Arias, R. Daniel, A. C. Junior, and B. J. T. Fernandes, “Ceramic Cracks Segmentation with Deep Learning,” Applied Sciences 2021, Vol. 11, Page 6017, vol. 11, no. 13, p. 6017, Jun. 2021, doi: 10.3390/APP11136017.

K. J. Wang, H. Fan-Jiang, and Y. X. Lee, “A multiple-stage defect detection model by convolutional neural network,” Comput Ind Eng, vol. 168, p. 108096, Jun. 2022, doi: 10.1016/J.CIE.2022.108096.

J. Li, N. Cai, Z. Mo, G. Zhou, and H. Wang, “IC solder joint inspection via generator-adversarial-network based template,” Mach Vis Appl, vol. 32, no. 4, pp. 1–16, Jul. 2021, doi: 10.1007/S00138-021-01218-1/TABLES/4.

X. Zheng, J. Chen, H. Wang, S. Zheng, and Y. Kong, “A deep learning-based approach for the automated surface inspection of copper clad laminate images,” Applied Intelligence 2020 51:3, vol. 51, no. 3, pp. 1262–1279, Sep. 2020, doi: 10.1007/S10489-020-01877-Z.

H. G. Nguyen, R. Habiboglu, and J. Franke, “Enabling deep learning using synthetic data: A case study for the automotive wiring harness manufacturing,” Procedia CIRP, vol. 107, pp. 1263–1268, Jan. 2022, doi: 10.1016/J.PROCIR.2022.05.142.

A. Kulkarni and C. Xu, “A Deep Learning Approach in Optical Inspection to Detect Hidden Hardware Trojans and Secure Cybersecurity in Electronics Manufacturing Supply Chains,” Front Mech Eng, vol. 7, Jul. 2021, doi: 10.3389/FMECH.2021.709924.

N. Hussain et al., “A deep neural network and classical features based scheme for objects recognition: an application for machine inspection,” Multimed Tools Appl, pp. 1–23, Apr. 2020, doi: 10.1007/S11042-020-08852-3/TABLES/8.

L.-C. Chen et al., “Edge-glued wooden panel defect detection using deep learning,” Wood Sci Technol, vol. 56, no. 2, pp. 477–507, 2022, doi: 10.1007/s00226-021-01316-3.

T.-H. Kim, H.-R. Kim, and Y.-J. Cho, “Product Inspection Methodology via Deep Learning: An Overview,” Sensors , vol. 21, no. 15. 2021. doi: 10.3390/s21155039.

J. Lehr, A. Sargsyan, M. Pape, J. Philipps, and J. Krüger, “Automated Optical Inspection Using Anomaly Detection and Unsupervised Defect Clustering,” IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, vol. 2020-September, pp. 1235–1238, Sep. 2020, doi: 10.1109/ETFA46521.2020.9212172.

X. Zheng, H. Wang, J. Chen, Y. Kong, and S. Zheng, “A Generic Semi-Supervised Deep Learning-Based Approach for Automated Surface Inspection,” IEEE Access, vol. 8, pp. 114088–114099, 2020, doi: 10.1109/ACCESS.2020.3003588.

Y. Yang et al., “A lightweight deep learning algorithm for inspection of laser welding defects on safety vent of power battery,” Comput Ind, vol. 123, Dec. 2020, doi: 10.1016/j.compind.2020.103306.

Y. F. Chen, F. S. Yang, E. Su, and C. C. Ho, “Automatic Defect Detection System Based on Deep Convolutional Neural Networks,” 2019 International Conference on Engineering, Science, and Industrial Applications, ICESI 2019, Aug. 2019, doi: 10.1109/ICESI.2019.8863029.

V. A. Adibhatla et al., “Unsupervised Anomaly Detection in Printed Circuit Boards through Student–Teacher Feature Pyramid Matching,” Electronics 2021, Vol. 10, Page 3177, vol. 10, no. 24, p. 3177, Dec. 2021, doi: 10.3390/ELECTRONICS10243177.

K.-C. Li et al., “Intelligent Identification of MoS2 Nanostructures with Hyperspectral Imaging by 3D-CNN,” Nanomaterials 2020, Vol. 10, Page 1161, vol. 10, no. 6, p. 1161, Jun. 2020, doi: 10.3390/NANO10061161.

B. M. Haddad, S. F. Dodge, L. J. Karam, N. S. Patel, and M. W. Braun, “Locally Adaptive Statistical Background Modeling with Deep Learning-Based False Positive Rejection for Defect Detection in Semiconductor Units,” IEEE Transactions on Semiconductor Manufacturing, vol. 33, no. 3, pp. 357–372, Aug. 2020, doi: 10.1109/TSM.2020.2998441.

T. W. Tang, W. H. Kuo, J. H. Lan, C. F. Ding, H. Hsu, and H. T. Young, “Anomaly Detection Neural Network with Dual Auto-Encoders GAN and Its Industrial Inspection Applications,” Sensors 2020, Vol. 20, Page 3336, vol. 20, no. 12, p. 3336, Jun. 2020, doi: 10.3390/S20123336.

T. C. Tsan, T. F. Shih, and C. S. Fuh, “TsanKit: artificial intelligence for solder ball head-in-pillow defect inspection,” Mach Vis Appl, vol. 32, no. 3, May 2021, doi: 10.1007/S00138-021-01192-8.

J. Villalba-Diez, D. Schmidt, R. Gevers, J. Ordieres-Meré, M. Buchwitz, and W. Wellbrock, “Deep Learning for Industrial Computer Vision Quality Control in the Printing Industry 4.0,” Sensors 2019, Vol. 19, Page 3987, vol. 19, no. 18, p. 3987, Sep. 2019, doi: 10.3390/S19183987.

Y. Shih, C. C. Kuo, and C. H. Lee, “Low-Cost Real-Time Automated Optical Inspection Using Deep Learning and Attention Map,” Intelligent Automation & Soft Computing, vol. 35, no. 2, pp. 2087–2099, Jul. 2022, doi: 10.32604/IASC.2023.027659.

S. Mei, Q. Cai, Z. Gao, H. Hu, and G. Wen, “Deep Learning Based Automated Inspection of Weak Microscratches in Optical Fiber Connector End-Face,” IEEE Trans Instrum Meas, vol. 70, 2021, doi: 10.1109/TIM.2021.3059105.

H. Yang, S. Mei, K. Song, B. Tao, and Z. Yin, “Transfer-Learning-Based Online Mura Defect Classification,” IEEE Transactions on Semiconductor Manufacturing, vol. 31, no. 1, pp. 116–123, Feb. 2018, doi: 10.1109/TSM.2017.2777499.

Q. Zhang et al., “Deep learning based solder joint defect detection on industrial printed circuit board X-ray images,” Complex and Intelligent Systems, vol. 8, no. 2, pp. 1525–1537, Apr. 2022, doi: 10.1007/S40747-021-00600-W/FIGURES/12.

T. Czimmermann et al., “Visual-Based Defect Detection and Classification Approaches for Industrial Applications—A SURVEY,” Sensors 2020, Vol. 20, Page 1459, vol. 20, no. 5, p. 1459, Mar. 2020, doi: 10.3390/S20051459.

S. Shahrabadi, Y. Castilla, M. Guevara, L. G. Magalhães, D. Gonzalez, and T. Adão, “Defect detection in the textile industry using image-based machine learning methods: A brief review,” J Phys Conf Ser, vol. 2224, no. 1, Apr. 2022, doi: 10.1088/1742-6596/2224/1/012010.

A. A. R. M. A. Ebayyeh and A. Mousavi, “A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry,” IEEE Access, vol. 8, pp. 183192–183271, 2020, doi: 10.1109/ACCESS.2020.3029127.

D. U. Lim, Y. G. Kim, and T. H. Park, “SMD Classification for Automated Optical Inspection Machine Using Convolution Neural Network,” Proceedings - 3rd IEEE International Conference on Robotic Computing, IRC 2019, pp. 395–398, Mar. 2019, doi: 10.1109/IRC.2019.00072.

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Jonathan Sanchez-Romero, Joe Llerena-Izquierdo

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Licensing Agreement

This journal provides free access to its content through its website following the principle that making research available free of charge to the public supports a larger exchange of global knowledge.

Web content of the journal is distributed under a Attribution-NonCommercial-ShareAlike 4.0 International.

Authors may adopt other non-exclusive license agreements for the distribution of the version of the published work, provided that the initial publication in this journal is indicated. Authors are allowed and recommended to disseminate their work through the internet before and during the submission process, which can produce interesting exchanges and increase citations of the published work.