Manufacturing and characterization of high entropy alloys

DOI:

https://doi.org/10.18779/ingenio.v5i2.519Keywords:

High entropy alloys, mechanical alloying, aluminum, mechanical propertiesAbstract

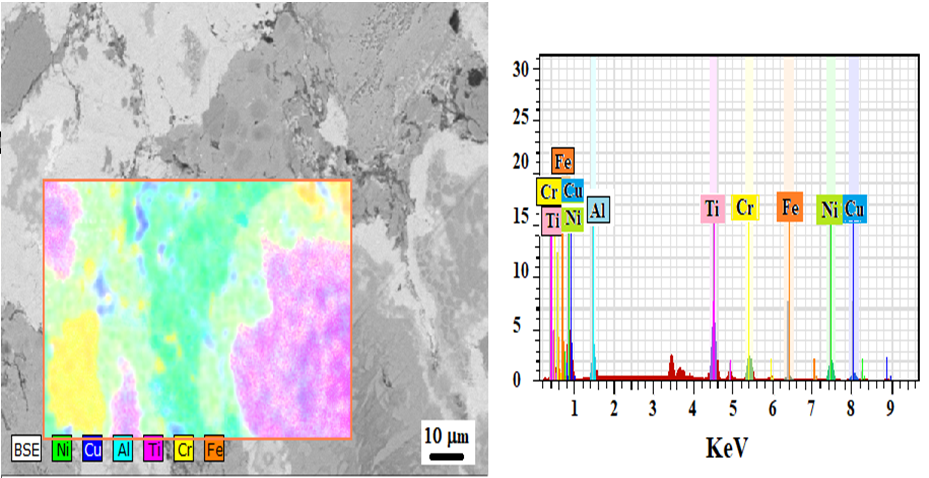

High entropy alloys are a new kind of multicomponent alloys, consisting of five or more metallic elements with equiatomic proportions. Despite the large number of alloying elements, HEA can exhibit simple solid solution phases, such as face- and body-centered cubic phases. In this work, the AlxCrCuFeNiTi (x = 0, 0.45, 1, 2.5, 5 mol) alloy was fabricated by mechanical alloying to determine the effect of aluminum on the phase evolution during the process and its impact on the mechanical properties. Grinding of the powders was carried out at 300 rpm during 180 minutes. The powders resulting from milling were pressed at 250 kg/cm2. The pressed samples were sintered at 1,300°C during 1 hour. From results it can be seen that with increasing Al concentration, the alloys undergo a transformation from a single FCC phase to mixture of FCC and BCC phases, as well as the precipitation of FeAl3, Al3Ni, TiAl and Ti3Al intermetallics. The alloy that achieved the highest hardness was the one with the highest Al content. These alloys harden significantly with the addition of Al, due to the BCC phase formation and intermetallic compounds.

Downloads

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, “Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes,” Adv Eng Mater, 6, 299-303, 2004.

C.Y. Hsu, J.W. Yeh, S.K. Chen and T.T. Shun, “Wear resistance and high-temperature compression strength of FCC CuCoNiCrAl0.5Fe alloy with Boron addition,” Metall. Mater. Trans. A 35, 1465-1469, 2004.

P.K. Huang, J.W. Yeh, T.T. Shun and S.K. Chen, “Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating,” Adv Eng Mater 6, 74-78, 2004.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, “Microstructural development in equiatomic multicomponent alloys,” Mater. Sci. Eng., A 375-377, 213-218, 2004.

A.M. Manzoni, S. Singh, H.M. Daoud, R. Popp, R. Volkl, U. Glatzel, N. Wanderka, “On the Path to Optimizing the Al-Co-Cr-Cu-Fe-Ni-Ti High Entropy Alloy Family for High Temperature Applications,” ENTROPY,18, 4, 104-109, 2016.

S.I. Vorobiov, D.M. Kondrakhova, S.A. Nepijko, D.V. Poduremne, N.I. Shumakova, I.Y. Protsenko, “Crystalline Structure, Electrophysical and Magnetoresistive Properties of High Entropy Film Alloys,” Journal of Nano and Electronic Physics, 11, 2, 1-6, 2016.

S.T. Chen, W.Y. Tang, Y.F. Kuo, S.Y. Chen, C.H. Tsau, T.T. Shun, J.W. Yeh, “Microstructure and properties of age-hardenable AlxCrFe1.5MnNi0.5 alloys,” Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 527, 21-22, 5818-5825, 2010.

A.M. Manzoni, S. Singh, H.M. Daoud, R. Volkl, U. Glatzel, N. Wanderka, N, “On the Optimization of the Microstructure and Mechanical Properties of Al-Co-Cr-Cu-Fe-Ni-Ti -Based High Entropy Alloys,” Jordan Journal of Physics, 8, 3, 177-186, 2015.

D.H. Xiao, P.F. Zhou, W.Q. Wu, H.Y. Diao, M.C. Gao, M. Song, P.K. Liaw, “Microstructure, mechanical and corrosion behaviors of AlCoCuFeNi-(Cr,Ti) high entropy alloys,” Materials & Design, 116, 438-447, 2017.

C.W. Tsai, M.H. Tsai J.W., Yeh C.C. Yang CC, “Effect of temperature on mechanical properties of Al0.5CoCrCuFeNi wrought alloy,” J Alloys Compd, 490, 160-165, 2010.

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, O.N. Senkov, “Tensile properties of an AlCrCuNiFeCo high-entropy alloy in as-cast and wrought conditions,” Mater Sci Eng A, 533, 107-118, 2012.

Y.H. Fan, Y.P. Zhang, H.G. Guan, H.M. Suo and L. He, “AlNiCrFexMo0.2CoCu high entropy alloys prepared by powder metallurgy,” Rare Met Mater Eng, 42, 1127-1129, 2013.

M.V. Marych, G.A. Bagliuk, A.A. Mamonova, A.N. Gripachevskii, “The influence of production conditions on the structure, phase composition, and properties of the high-entropy Ti-Cr-Fe-Ni-Cu alloy,” Powder Metallurgy and Metal Ceramics, 57, 9-10, 533-541, 2019.

C.D. Gomez-Esparza, F. Baldenebro-Lopez, L. Gonzalez-Rodelas, J. Baldenebro-Lopez, R. Martinez-Sanchez, “Series of Nanocrystalline NiCoAlFe(Cr, Cu, Mo, Ti) High- Entropy Alloys produced by Mechanical Alloying,” Materials Research-Ibero-American Journal of Materials, 19, 39-46, 2016.

A.I. Yurkova, V.V. Chernyavskii, V.F. Gorban', “Structure and Mechanical Properties of High-Entropy AlCuNiFeTi and AlCuNiFeCr Alloys Produced by Mechanical Activation Followed by Pressure Sintering,” Powder Metallurgy and Metal Ceramics, 55, 3-4, 152-163, 2016.

G.A. Baglyuk, M.V. Marich, A.A. Mamonova, A.N. Gripachevskii, “Features of Structurization During Sintering of Compacts from a Multicomponent Ti-Cr-Fe-Ni-Cu Charge,” Powder Metallurgy and Metal Ceramics, 54, 9-10, 543-547, 2016.

R. Sriharitha, B.S. Murty, R.S. Kottada, “Phase formation in mechanically alloyed AlxCoCrCuFeNi (x=0.45, 1, 2.5, 5 mol) high entropy alloys,” Intermetallics, 32, 119-126, 2013.

Y.L. Chen, Y.H. Hu, C.A. Hsieh, J.W. Yeh, S.K. Chen, “Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system,” Journal of Alloys and Compounds, 481, 1-2, 768-775, 2009.

Y.L. Chen, Y.H. Hu, C.W. Tsai, C.A. Hsieh, S.W. Kao, J.W. Yeh, T.S. Chin, S.K. Chen, Alloying behavior of binary to octonary alloys based on Cu-Ni-Al-Co-Cr-Fe-Ti-Mo during mechanical alloying,” Journal of Alloys and Compounds, 477, 1-2, 696-705, 2009.

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou and E.J. Lavernia, “Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy,” Acta Mater, 107 59-71, 2016.

A.M. Manzonia, U. Glatzelb, “New multiphase compositionally complex alloys driven by the high entropy alloy approach,” Materials Characterization, 147, 512–532, 2019.

B. Cantor, “Multicompent and High Entropy Alloys,” Entropy, 16, 4749-4768, 2014.

B.E. MacDonald, Z. Fu, B. Zheng, W Chen, Y Lin, F Chen, L. Zhang, J Ivanisenko, Y Zhou, H Hahn and E, J. Lavernia, “Recent Progress in High Entropy Alloy Research”, JOM, 69, 10, 2024–2031, 2017.

ASTM C20-00 (2010). Standard test methods for apparent porosity, water absorption, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water.

ASTM C1327 (2015), Standard test method for Vickers indentation hardness of advanced ceramics.

Y.J. Zhou, Y. Zhang, Y.L. Wang, & G.L. Chen, “Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties”, Applied Physics Letters, 90(18), 181904, 2007.

J.F. Shackelford, Y. Han, S. Kim, & S. Kwon, CRC Materials Science and Engineering Handbook (English Edition) (4.a ed.). CRC Press, 2016.

J. He, W. Liu, H. Wang, Y. Wu, X. Liu, T. Nieh, & Z. Lu, “Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system”, Acta Materialia, 62, 105–113, 2014.

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Enrique Rocha-Rangel, José A. Castillo-Robles , José A. Rodríguez-García , Eddie N. Armendáriz-Mireles

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Licensing Agreement

This journal provides free access to its content through its website following the principle that making research available free of charge to the public supports a larger exchange of global knowledge.

Web content of the journal is distributed under a Attribution-NonCommercial-ShareAlike 4.0 International.

Authors may adopt other non-exclusive license agreements for the distribution of the version of the published work, provided that the initial publication in this journal is indicated. Authors are allowed and recommended to disseminate their work through the internet before and during the submission process, which can produce interesting exchanges and increase citations of the published work.